1. Introduction

This Outline Construction Environmental Management Plan (OCEMP) refers to the construction of the onshore transmission works of the Berwick Bank Wind Farm, an offshore wind project, by Berwick Bank Wind Farm Limited (BBWFL) (hereafter referred to as “the Applicant”), a wholly owned subsidiary of SSE Renewables Limited (“SSER”). Berwick Bank Wind Farm (hereafter referred to as “the Project”) includes both the offshore and onshore infrastructure required to generate and transmit electricity from the offshore array area to a Scottish Power Energy Networks (SPEN) 400kV Grid Substation located onshore at Branxton, southwest of Torness Power station.

The onshore transmission works (hereafter referred to as “the Proposed Development”) comprises the onshore elements of the Project, located on the landward side of Mean Low Water Springs (MLWS). The key components of the Proposed Development, which this OCEMP covers, are:

- cable landfall

- onshore substation

- onshore cables within a cable corridor between the cable landfall and the new onshore substation, and between the new onshore substation and the National Grid Branxton substation; and

- associated ancillary infrastructure.

The OCEMP will be updated and finalised post consent in line with any relevant planning conditions and in agreement with East Lothian Council (ELC).

The full CEMP will form part of the induction which is mandatory for all employees, contractors and visitors attending the site. All employees and contractors shall familiarise themselves with the content of the CEMP.

1.1. Purpose

1.1. Purpose

The CEMP will be a key document assisting the Applicant and Principal Contractor in complying with set planning conditions and relevant legislation, policy, and guidance. The CEMP will be a live document, updated as required throughout the planning and construction process.

The aim of this OCEMP is to establish the main mitigation and control measures that will be utilised to provide robust environmental management throughout the construction period to avoid or minimise the adverse effects of the Proposed Development. On confirmation of Principal Contractor, the OCEMP will be updated to reflect specific proposed construction methods and the document reviewed and agreed with ELC before construction works begin. The CEMP will therefore evolve and is subject to refinement, amendment, and expansion as necessary.

Throughout the planning and construction phases of the Proposed Development, the CEMP will be subject to continual review, for example:

- To address any conditions stipulated in the Planning Permission;

- To address any update in current legislation;

- To ensure it reflects good practice during construction;

- To ensure it incorporates the findings of any pre-construction site investigations and surveys; and

- To accommodate the working practices of the appointed Principal Contractor.

1.2. Content

1.2. Content

This document sets out the minimum standards to be adopted when constructing the Proposed Development. It also provides information about the associated Management Plans which should be read in conjunction with this CEMP.

- Outline Pollution Prevention and Contingency Plan;

- Outline Construction Noise & Vibration Management Plan;

- Outline Construction Dust and Air Quality Management Plan;

- Outline Site Waste Management Plan;

- Outline Water Quality Management Plan;

- Outline Soils Management Plan;

- Outline Habitat Management Plan;

- Outline Species Protection Plan;

- Outline Construction Traffic Management Plan; and

- Outline Archaeological Management Plan

1.3. Site and Surroundings

1.3. Site and Surroundings

The Proposed Development location is provided in the Environmental Impact Assessment (EIA) Report Volume 2 Figure 1.1 The extent of the Proposed Development red line Planning Application Boundary (hereafter referred to as “the site”) is situated near Torness and the village of Innerwick, south-east of Dunbar in East Lothian, Scotland. The centre of the site is OSGB36, British National Grid (BNG) 374080, 673982. The site is approximately 598 ha in size.

The proposed cable landfall is located north-west of Torness Power Plant and Skateraw harbour. The onshore cable corridor runs west of the settlement of Skateraw, under the East Coast Main Line (ECML) railway and the A1 trunk road, to the onshore substation, located in open agricultural land north-east of Innerwick. The onshore cable corridor then runs south through agricultural land between Innerwick and Thorntonloch Glen, crossing underneath overhead power lines, to continue south of the Braidwood Burn and the proposed location of the National Grid Branxton substation.

The site is predominantly arable, open agricultural land, interspersed with rural properties and crossed by transport routes including the ECML and the A1. There is industrial development in the wider vicinity including Torness Power Plant and Oxwell Mains Cement Works and Quarry on the coastline.

Further details of the site and its surroundings are provided in EIA Report Volume 1, Chapter 5.

1.4. Proposed Development Description

1.4. Proposed Development Description

The Proposed Development comprises the following buildings and infrastructure, which have been considered in this OCEMP:

- Onshore substation; within an agricultural field currently used for arable agriculture, approximately 680 m north-east of Innerwick settlement. Landfall and Transition Joint Bays; eight proposed transition joint bays located approximately 130 m north-west of Skateraw harbour, to connect the offshore and onshore cables.

- Onshore Cables; onshore cables installed underground through agricultural land.

- Permanent Access Road; a new permanent access road to the onshore substation to the southwest.

- Temporary Access Road; constructed within the site along the length of the onshore cable corridor. The temporary access roads will be maintained for the duration of the construction period as required. Following construction, the temporary surface will be removed and the previous land use reinstated.

- Construction Compounds; multiple temporary construction compounds erected across the site.

- Trenchless Technology Compounds; required to enable onshore cables to be routed beneath locations including; landfall, the East Coast Mainline (ECML) railway, the A1 trunk road and existing cable infrastructure, and beneath a scheduled monument.

- Sustainable Drainage System Pond; located in the east of the onshore substation.

- A cable bridge crossing of the Braidwood Burn.

Further details on each infrastructure component are provided in the EIA Report Volume 1, Chapter 5.

2. Document Control

2. Document Control

The CEMP is a “live” document and will be subject to periodic review and updating. The document is intended for use by the Applicant and their contractors specifically involved in the construction of the Proposed Development. When this document is amended, the document control table will be updated (Table 1) and it will be issued to all personnel specified on the distribution list below (Table 2), which will be updated with relevant details at the stage of submission of the full CEMP.

3. Responsibilities

3. Responsibilities

3.1. Environmental Policy and Management Systems

3.1. Environmental Policy and Management Systems

The Principal Contractor will ensure that copies of their environmental policies are clearly displayed on site notice boards during the construction period. All employees are expected to comply with the requirements of the Environmental Policy and the requirements of the Environmental Management System (EMS) under a suitable accreditation such as ISO14001.

The Applicant and the Principal Contractor expects their employees and support staff (contractors, sub-contractors, suppliers etc.) to actively promote and administer a strong environmental culture. To achieve this, a number of initiatives will be implemented during the construction phase from Day One. This will include the use of environmental inductions, poster campaigns to raise awareness of topical subjects (such as seasonal activities and timings) and toolbox talks (TBT) involving all members of the project team and site workforce.

As part of the EMS for the site, a Project Environmental File (PEF) will be maintained by the Principal Contractor. Within this PEF, a legislation register will be stored which will be reviewed periodically and updated as necessary. Any changes to relevant environmental legislation will be disseminated to project management immediately, after which the method statements of any affected construction activities will be amended as necessary.

3.2. Consents and Licences

3.2. Consents and Licences

A register of required consents and licences will be held in the PEF, including the relevant reference numbers, and responsible/named competent persons.

3.3. Roles and Responsibilities

3.3. Roles and Responsibilities

It is the responsibility of all staff involved with the Proposed Development, including the Applicant, Principal Contractor, and sub-contractors, to ensure the correct implementation of the CEMP and the environmental mitigation contained within.

The key environmental responsibilities during the construction phase of the Proposed Development are summarised below:

- The Applicant – responsible for ensuring that the Proposed Development is built in accordance with the planning conditions and that all environmental mitigation measures stated within the EIA Report and the CEMP are implemented.

- Principal Contractor – responsible for regularly reviewing and updating the CEMP and ensuring that all staff and sub-contractors abide by and implement the CEMP. The Principal Contractor will be responsible for the implementation of the CEMP and all the environmental mitigation measures outlined in the EIA Report.

- Consents and Environment Manager – A Consents and Environment Manager (CEM) will be appointed as part of the Applicant’s or Principal Contractor’s team. They shall have overall responsibility for the management of the construction phase. The Applicant and Principal Contractor will ensure that a suitable, independent person with appropriate knowledge and experience of similar scale or type of projects will be employed.

The CEM will:

– Programme any required pre-construction surveys and samples into the construction schedule and continue with any monitoring to be undertaken during construction as required. These will then be the responsibility of the ECoW (Ecological Clerk of Works);

– Progress any discharge of conditions, especially those that require access agreements to be in place to allow for pre-commencement sampling or surveying to be undertaken;

– Ensure all required consents are in place before work starts and compliance with consents;

– Ensure that all mitigation measures and commitments are implemented properly and effectively;

– Supervise construction processes with potential for environmental consequences such as trenchless technology operations and installation of temporary site drainage;

– Ensure compliance with the topic-specific Management Plans by, for example, undertaking spot checks and audits on the timing of Heavy Goods Vehicles (HGVs) and abnormal load deliveries, speed checks on the approach to site and along access tracks throughout the site, and observations of works in sensitive areas (if not already undertaken by a specific ECoW);

– Undertake weekly audits/site checks;

– Ensure environmental and waste requirements are included on requisitions and in subcontracts and orders;

– Ensure oil, including diesel, is stored in properly bunded tanks/drip trays;

– Report incidents and non-conformances to the Applicant, Principal Contractor, and relevant authorities in line with the reporting procedure in this CEMP;

– Include environmental performance, review of contract objectives and targets (including environmental), review of incidents and non-conformances at the project review meetings;

– Ensure employees and subcontractors implement the controls outlined in the finalised and approved CEMP and any other appropriate plans, mitigation measures or commitments;

– Ensure employees and subcontractors receive induction training (including project environmental issues) and toolbox talks, as appropriate;

– Ensure personnel needed for audits are available when required; and

– Verify actions resulting from corrective action requests and observations raised during audits are completed by the deadlines.

The CEM will also act as the main point of contact between the:

– Regulators such as ELC and SEPA;

– Local stakeholders;

– Local communities; and

– The public and visitors to the area.

The CEM will be the focal point for queries, comments, and questions on project progress meetings, reporting and also communication on critical activities of the Proposed Development. This will include communicating when pre-construction works are likely to commence and then keeping the local communities and stakeholders aware of the continuing activities which will occur during the construction phase including regular updates on progress.

The CEM will specifically communicate the following construction activities to local communities (please note this list is not exhaustive):

– Works which involve the loss or temporary replacement of access (for example road diversions or closures, or impacts to recreational routes);

– Works adjacent to or within key sensitive areas such as watercourses;

– Progress/compliance with mitigation measures and reporting;

– Notification of monitoring at relevant locations, including requests for permission to access third party land or property where there is a proposed monitoring or sampling point; and

– Changes in working hours, particularly any proposed out-of-hours working.

Once the Principal Contractor is appointed and the construction programme confirmed, the CEM will communicate this programme to the community and facilitate meetings as required.

The CEM will ensure that records of communication (including verbal communication) are kept, and that regular reporting is provided to ELC, SEPA and the local communities.

- Ecological Clerk of Works (ECoW) – reports to the CEM and is responsible for monitoring the implementation of the landscape and ecological mitigation measures on site prior to, during and post-construction. The ECoW will be a Suitability Qualified Ecologist (SQE).

- Archaeological Clerk of Works (ACoW) – employed to oversee the archaeological programme of works and will be responsible for the successful implementation of the Archaeological Management Plan (AMP).

- All construction staff – responsible for understanding the requirements of the CEMP and the environmental sensitivities of the Proposed Development. All staff have an obligation to abide by the CEMP and the relevant environmental legislation.

3.4. Subcontractor Management

3.4. Subcontractor Management

The project will engage various subcontractors to carry out project construction related activities. These subcontractors are responsible for performing all work in conformance with relevant environmental legislation, the requirements of the CEMP, and contractual environmental requirements.

Subcontractors are required to develop suitable, adequate, and effective method statements that explicitly define the measures to be taken to manage significant environmental risks associated with their scope of works. No works will be permitted to commence until such method statements have been developed and approved by the CEM. Additionally, subcontractors are required to provide sufficient and competent resources to monitor conformance with their own defined method statements.

The Principal Contractor will conduct monthly Environmental Reviews that will assess the environmental performance of subcontractors.

4. Program of Works

4. Program of Works

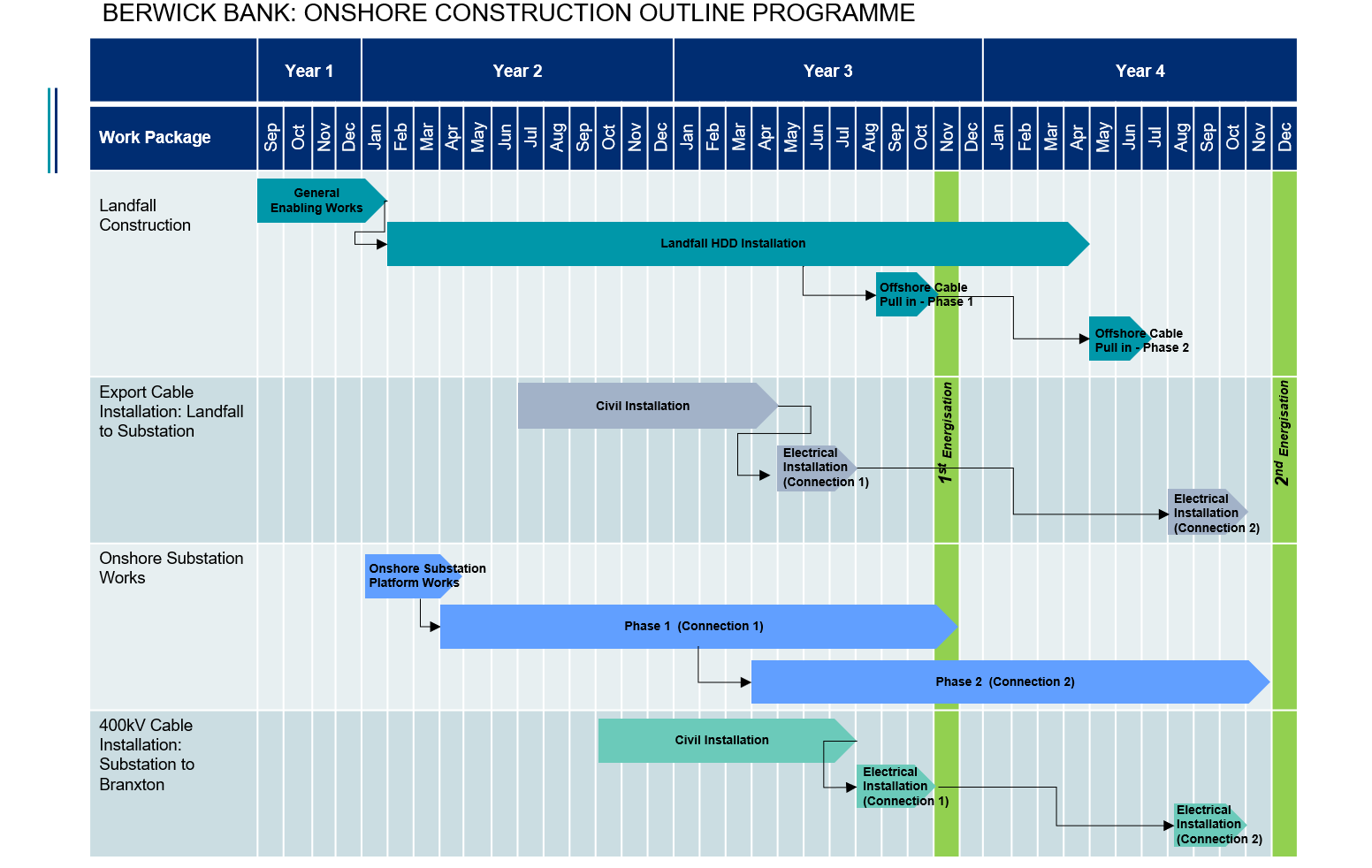

The current indicative construction programme for the Proposed Development outlines the key construction activities and the timescales within which these activities are planned to take place (see Figure 4.1). On-site activities will not necessarily be ongoing for the entire duration of each indicated timescale. This construction programme indicates an estimated final installation date in 2030.

Figure 4.1 - Indicative development and installation programme for the Proposed Development

5. Safety

5. Safety

Site specific risk assessments and method statements will be undertaken in accordance with the applicable legislation prior to the commencement of construction activities; to identify any potential risks, assess their likelihood and significance, and to identify mitigation measures to be implemented to ensure the safety of workers and the general public.

Site security during the construction phase will be strict. Access to the site will be prevented by the use of temporary fencing to prevent unauthorised access. Compounds for the temporary storage of equipment or materials will be provided, with segregation of materials (hazardous or otherwise) as required, and designated re-fuelling areas. These will be locked with restricted access. Security staff will be utilised as appropriate.

The Applicant will ensure that adequate arrangements are in place for the discharge of all duties under the Construction (Design and Management) (CDM) Regulations 2015.

A Health and Safety Plan will be prepared by the Principal Contractor which will set out how all health and safety matters on site are to be managed and how risks are to be identified and managed in accordance with current good practice and legal requirements.

6. Security

6. Security

A Permit to Work system (or equivalent) will be introduced during construction to ensure that only authorised construction personnel are allowed within the construction area and that an accurate record of site-based personnel is available in case of emergency.

The Principal Contractor will ensure that the construction sites are secure. Access to the site will be limited to specified entry points only and all personnel entrances and exits will be recorded and monitored for both security and health and safety purposes.

Visitors to the Proposed Development site during construction will be required to report to the construction reception office (location to be confirmed) and will only be permitted to access the construction area under escort by appropriately authorised staff or following successful completion of specific safety induction training.

All working areas will be appropriately fenced off from members of the public and to prevent animals from straying onto working areas.

7. Construction Operations

7. Construction Operations

7.1. Site Access

7.1. Site Access

Access to each element of the Proposed Development (Onshore Substation, Cable Landfall and Onshore Cable Route) will be via the A1 trunk road (A1(T)) and subsequently by the local road network. These accesses will be agreed with ELC and Transport Scotland and will be detailed in the final Construction Traffic Management Plan (CTMP).

7.2. Construction and Delivery Hours

7.2. Construction and Delivery Hours

Planning permission is being sought for 24-hour, 7days per week construction working hours. The 24-hour construction period is anticipated to be only necessary for the trenchless solutions, as once drilling has started it needs to be completed regardless of the time of day. Other construction works will be limited where practicable to weekday daytimes and Saturday mornings. As such, any necessary night time working will be minimised as far as reasonably practicable.

The majority of deliveries will be programmed to arrive during normal working hours only. Night-time deliveries will be minimal and will only be undertaken with special consideration. Care will be taken to minimise noise when unloading vehicles, and construction traffic will be prohibited from unnecessary idling within the site boundary or at the site access points.

Works will be phased to minimise effects on the surrounding environment and local communities by:

- Scheduling construction activities to minimise the area and period of time that soil will be exposed, particularly during wetter periods;

- Timing soil handling and overburden stripping to suit weather conditions;

- Timing noise, vibration and dust producing activities to avoid key sensitive times most disturbing to the local residential and commercial properties; and

- Scheduling works to minimise disruption to pastoral farming activities.

7.3. Construction Site Housekeeping

7.3. Construction Site Housekeeping

Good construction site housekeeping practice will be applied at all times. As far as reasonably practicable, the layout of the site will be designed using the following principles:

- All work areas will be secured;

- Any fuels or liquid materials will be stored and bunded in compliance with the relevant regulations;

- Signage and boundary fences, where required, will be regularly inspected, repaired, and replaced as necessary;

- All working areas will be kept in a clean and tidy condition;

- Wheel washing and dust suppression facilities will be provided when and where required;

- All practicable measures will be taken to minimise the risk of fire and the Principal Contractor will comply with the requirements of the local fire authority;

- Waste will be removed at frequent intervals;

- Construction waste susceptible to spreading by wind or liable to cause litter will be stored in secure containers;

- The Principal Contractor shall take all necessary and practicable precautions to prevent the occurrence of smoke emissions or fumes from site plant or stored fuel oils for safety reasons and to prevent, as far as is reasonably practicable, such emissions or fumes drifting into residential areas, nearby workplaces, or areas of public open space. In particular:

– Plant shall be well maintained, regularly serviced and measures taken to ensure that engines are not left running for long periods when not directly in use;

– Plant which emits visible emissions after warm-up shall be taken out of service and either repaired or replaced; and

– Vehicle exhausts will be directed away from the ground and other surfaces and preferably upwards to avoid road dust being re-suspended to the air and should be positioned at a sufficient height to ensure adequate local dispersal of emissions.

- The Principal Contractor will ensure that all construction vehicles will conform to at least Euro 4 emissions standards;

- Open fires will not be permitted on site; and

- All works, at all phases of the Proposed Development, will be undertaken in accordance with SEPA Pollution Prevention Guidelines (PPG) and Guidance on Pollution Prevention (GPP) (which will ultimately replace PPGs).

7.4. Pre-construction Enabling Works

7.4. Pre-construction Enabling Works

Prior to any enabling or pre-construction works, no topsoil stripping will be undertaken without the written permission of ELC in consultation with the appropriate stakeholders.

All groundworks, clearing land and reprofiling will take into consideration the Guidance contained within SEPA’s Supporting Guidance (WAT-SG-75) Sector Specific Guidance: Construction Sites (February 2018), which provides guidance on the application of environmental standards and good management practice techniques in relation to large scale construction sites and pollution control.

7.5. Construction Compound

7.5. Construction Compound

Temporary site infrastructure is expected to consist of, but not be limited to, boundary fencing, security lighting, temporary construction site facilities (welfare cabins, stores, skips, etc.), and storage for Control of Substances Hazardous to Health (COSHH) substances. Power for the temporary facilities during the construction phase will comprise temporary connection to the local grid and mobile diesel generator. The type and exact location will be selected by the Principal Contractor and confirmed in a later revision to this document.

The Construction Compounds will meet standard good management practices which include but are not limited to:

- Compound design and layout will align with standards for distances from watercourses;

- Appropriate temporary drainage and settlement ponds to manage anticipated surface water run-off from the compound area;

- Bunds will be used where required to meet the requirements of the SEPA PPGs and oil storage regulations;

- Adequate parking will be provided to ensure that the safety and efficient operation of the public highway is not reduced;

- Welfare facilities will be provided to minimise the need for offsite trips by staff during the working day;

- Compound design and layout will ensure that dust emission sources are located away from sensitive receptors; and

- If compound lighting is required, it will be designed to minimise light pollution to the surrounding area.

7.6. Welfare Facilities

7.6. Welfare Facilities

Workers’ Safety Information Sheets and COSHH safety data sheets will be kept on site.

Where portable generators are used, industry good practice will be followed to minimise noise and pollution from such generators.

Prior to construction, the Principal Contractor will prepare the arrangements for welfare provision and will be responsible for the maintenance of the facilities throughout the construction of the Proposed Development. The nature and scale of facilities required will be in proportion to the size and location of the Proposed Development. Facilities will include:

- Toilets;

- Washing facilities;

- Changing rooms, drying rooms and lockers; and

- Canteen and kitchen facilities.

All foul waste will be disposed of by an appropriate contractor to a suitably licenced facility. It is expected that a suitably sized storage tank will be provided and will be periodically pumped out by a specialist contractor so that the water could be disposed of at a suitably licenced waste facility.

The risk of infestation by pests or vermin will be minimised by the appropriate collection, storage and regular collection of waste, the prompt treatment of any pest infestation and effective preventative pest control measures.

Wastewater facilities will be arranged with appropriate sewerage provisions included within these facilities and all necessary consents obtained from ELC and SEPA.

7.7. Artificial Lighting

7.7. Artificial Lighting

At night and during periods of darkness, directional security lighting will be used. Lighting will be selected and sited to minimise visual intrusion to local communities, residences, and environmental receptors, whilst maintaining the safe and efficient operation of the Proposed Development.

The Principal Contractor will comply with the requirements of the Environmental Protection Act (UK Government, 1990). As well as implementing relevant measures set out in the Guidance Notes for the Reduction of Obtrusive Light GN01:2011 (Institute of Lighting Professions, 2011). Measures to reduce the impacts of artificial lighting include:

- Unnecessary lighting will be avoided and, following completion of the task, lighting will be switched off and/or removed. All lighting will be switched off during daylight hours;

- All lighting will be designed to avoid visual intrusion and/or light spillage. Lighting will be positioned and directed to avoid nuisance to residents and wildlife and/or causing distractions to drivers on adjacent roads. Lighting will also avoid spillage onto neighbouring habitats; and

- Where mobile lighting relies on portable diesel generators for power, the containment of the diesel will be monitored to check for leaks and spills. Spill kits will be made available, and staff provided with appropriate training on their use.

7.8. Storage of Plant and Materials

7.8. Storage of Plant and Materials

Fuel, equipment, and construction materials will be stored appropriately so as to minimise the risk of pollution. The following measures will be implemented to prevent spillage of hazardous materials:

- Development of a Spill Response Plan and provision and maintenance of spill response equipment.

- Storage of hazardous materials no less than 20 m away from a watercourses/drainage gully.

- Completion of a COSHH assessment for hazardous materials.

- Development of a COSHH Register documenting materials stored and handling requirements.

- Segregation of COSHH raw material stores and COSHH waste stores.

- Storage of hazardous material containers on secondary containment systems that will contain 110% of the contents of the largest container or 25% of the total, whichever is greater.

- Protection of hazardous materials in locked containers to minimise the ingress of rainwater and secure them against accidental damage.

- Staff training in the use of spill kits and the correct disposal of used material.

- Maintenance of a log of any incidents; and

- Inspection of all construction plant and machinery on a daily basis to check for fuel and oil leaks and, where necessary, drip trays or plant nappies will be used to collect leaks.

7.9. Wheel Washing

7.9. Wheel Washing

The Principal Contractor will implement a wheel washing system (with rumble grids to dislodge accumulated dust and mud prior to leaving the site where reasonably practicable) to reduce debris on the public road network. The Principal Contactor will ensure there is an adequate area of hard surfaced road between the wheel wash facility and the site exit, wherever site size and layout permits.

7.10. Parking

7.10. Parking

Parking for construction workers, deliveries and site visitors will be accommodated within the Proposed Development site and will not impact on the public road network.

7.11. Site Demobilisation

7.11. Site Demobilisation

After the main construction activities have been finalised, permanent fencing will be installed where necessary, temporary infrastructure will be removed, and temporary compounds will be restored to previous land use.

8. Communication

8. Communication

8.1. Internal Meetings and Communication

8.1. Internal Meetings and Communication

Weekly internal construction meetings shall be held during the construction phase. These meetings shall include environmental matters and shall be attended by the CEM and ECoW. Any issues resulting from daily or weekly audits shall be discussed with appropriate corrective actions agreed. A ‘weekly look ahead’ shall be provided at the construction meeting where any environmental constraints or special requirements can be discussed and agreed in advance.

The CEM will attend any critical path or construction activities which have the potential to affect the local community and need to be communicated.

Environmental performance meetings will be arranged as necessary. These meetings will be attended as appropriate by the CEM, ECoW and representatives of the workforce. Notes of the meetings will be made available to all interested parties.

Site Environmental Notice Boards will display the Environmental Policy of the Applicant and the Principal Contractor, Emergency Contacts List, relevant statutory and non-statutory advice and guidance; and any other relevant information. These Environmental Notice Boards will be situated in prominent positions in the main reception area of the Proposed Development construction office.

8.2. External Meetings

8.2. External Meetings

The CEM will arrange and attend meetings with relevant statutory bodies as necessary together with the ECoW.

8.3. Community Liaison

8.3. Community Liaison

At the earliest possible stage, the Applicant will actively engage with local residents to discuss the programme of work, learn of any concerns they may have, and determine how the Principal Contractor can minimise the impacts of construction on local residents.

The CEM will be the first point of contact for any queries and/or grievances regarding the construction of the PD and will be responsible for:

- Recording all queries and/or issues raised;

- Responding in an appropriate and timely manner,

- Liaising with ELC and regulatory bodies as necessary in connection to any complaints; and

- Monitoring any actions that need to be implemented.

9. Environmental Training

9. Environmental Training

9.1. Inductions

9.1. Inductions

All project construction personnel and sub-contractors will receive an Environmental Induction. No personnel, including sub-contractors, will be permitted to undertake any work on site without undertaking a site induction. The site induction will evolve to reflect changes in the CEMP as the project develops. Environmental topics covered in the induction shall include, but will not be limited to:

- Water Resources;

- Pollution Prevention;

- Emergency Response Procedures;

- Waste Management and Housekeeping;

- Duties and Responsibilities;

- Relevant Procedures;

- Ecologically and Ornithological Sensitive Areas and Times;

- Incident and Non-Conformance Reporting;

- Consents, Licenses and Compliance;

- Legislation; and

- Environmental Good Practice.

9.2. Toolbox Talks

9.2. Toolbox Talks

Toolbox Talks (TBTs) on specialised topics shall supplement the Environmental Induction course. TBTs shall be used to highlight issues of concern and to disseminate any new information or responsibilities. They will also be used as a means of providing basic environmental training to crews on a specialised topic, e.g., water management. The TBTs also offer site personnel the opportunity to provide feedback.

TBTs will be provided routinely, but also when:

- There is a change to legislation, which requires an operational change;

- Site inspections or audits have identified corrective actions which require rolling out;

- Work is being undertaken in particularly sensitive areas; and

- When there are significant changes in environmental conditions, e.g., heavy rainfall.

Records of all TBTs undertaken, including attendance, will be maintained.

9.3. Specialist Training

9.3. Specialist Training

Specialist training for specific members of the construction crews will be provided as required. This may include, but will not be limited to:

- Environmental Incidents;

- Water management;

- Waste Representatives;

- Working near and in water; and

- Fuel Tanker Drivers and Refuellers.

10. Incident Response

10. Incident Response

10.1. Environmental Incidents and Corrective Actions

10.1. Environmental Incidents and Corrective Actions

All environmental incidents and near misses shall be reported and investigated by the CEM, reporting to the Applicant and Principal Contractor. Incidents will be recorded and those that, in the judgement of the CEM and/or ECoW, are deemed significant, will be reported to the Applicant and Principal Contractor as soon as possible. The Principal Contractor will comply with SSE Incident Reporting procedures including a 30 minute incident reporting line requirements. Where relevant, the appropriate authorities (e.g., NatureScot or SEPA) shall be informed immediately. Copies of incident investigation reports shall be supplied by the CEM to the Principal Contractor and the Applicant and action taken to prevent recurrence.

All corrective action, incident and near miss report forms shall be held in a register maintained at the construction site office base.

Any incident that may result in a significant adverse environmental impact, will be reported immediately to SEPA and ELC together with details of date, time, location, type, potential impact, and person calling.

10.2. Complaints Procedure

10.2. Complaints Procedure

The Principal Contractor will provide contact details to which all written complaints should be addressed. All complaints will be addressed by the CEM.

The Applicant will ensure that a system is introduced for the logging and recording of any complaints that will be collated and a copy made available to the Principal Contractor, CEM and the relevant department of ELC. Any complaints received will be acknowledged within 24 hours during all hours when works, including deliveries, are taking place. The CEM shall ensure that all complaints receive a written response, to include details of any action undertaken if such action is deemed appropriate. The CEM shall provide the Applicant with a monthly report that details all complaints, and the actions taken.

11. Environmental Monitoring

11. Environmental Monitoring

11.1. Overview

11.1. Overview

Environmental monitoring will be undertaken during construction works to check compliance with set conditions and applicable environmental legislation.

The CEM, ECoW and Principal Contractor will review all operations to ensure compliance with the CEMP. Should deficiencies or opportunities for improvement be identified, the CEM, ECoW and the Principal Contractor will agree the actions required and the timescale for implementation with the staff responsible. The Principal Contractor will be responsible for recording all deficiencies, the action taken to remedy the deficiency and the success of such action. They will report to the Applicant and to statutory bodies as required.

11.2. Inspections and Audits

11.2. Inspections and Audits

The CEM will undertake a programme of weekly environmental inspections and monthly environmental audits to record performance and identify any corrective actions required.

Provision will be made to carry out appropriate environmental inspections and monitoring of the Principal Contractor’s environmental performance in the form of monthly audits. Formal audits will be against an audit checklist which will provide a mechanism to monitor and assess legislative standards, licence conditions and any other provisions agreed with statutory undertakers.

Where problems are identified, corrective actions will be identified by the CEM and Principal Contractor and will be implemented by the Principal Contractor within a defined time frame.

The CEM and/or ECoW will inform the Principal Contractor and Applicant of any work that they feel should be stopped in order to avoid an unacceptable impact on the environment, in particular a breach of environmental legislation.

11.3. Specific Environmental Monitoring

11.3. Specific Environmental Monitoring

Monitoring of specific environmental parameters will be carried out as necessary and requirements for environmental monitoring will be reviewed as further consents and licences are received and consultations completed.

Table 3 presents the key parameters that may require environmental monitoring and where further details will be provided post consent and on appointment of a Principal Contractor.

Table 3: Key Parameters That Require Monitoring

12. Environmental Management Plans

12. Environmental Management Plans

Onshore environmental specific mitigation measures are provided in the EIA Report within relevant technical chapters in Volume 1, Chapters 6-14. Volume 4, Appendix 15.1 of the EIA Report provides a schedule of all mitigation. The Applicant and the Principal Contractor will adhere to these mitigation measures during construction of the Proposed Development.

The following sections provide further information on the topic specific Outline Management Plans. These will be updated by the Principal Contractor within the full management plans to be included within the CEMP and agreed with ELC.

12.1. Outline Pollution Prevention and Contingency Plan

12.1. Outline Pollution Prevention and Contingency Plan

12.1.1. Introduction

This section provides an overview of what will be included within the Pollution Prevention and Contingency Plan (PPCP). Measures relating specifically to water pollution from particulates and sediments in run-off are addressed within the Outline Water Quality Management Plan. The environmental control measures defined within the PPCP apply to all personnel and all activities and operations associated with the Proposed Development.

Post-consent, the PPCP will be prepared by the Principal Contractor and agreed with ELC, SEPA and NatureScot. This will include agreed emergency procedures in the event of a pollution incident. The PPCP will take into consideration the Guidance contained within SEPA’s Supporting Guidance (WAT-SG-75) Sector Specific Guidance: Construction Sites (SEPA, 2018), which provides guidance on the application of environmental standards and good management practice techniques in relation to large scale construction sites and pollution control.

12.1.2. Plant and Machinery

All plant and machinery shall be regularly maintained to ensure good working order. Checks for leaks of fuel and lubricants will be conducted before works with plant and machinery is allowed to commence and maintenance and servicing records will be reviewed and updated as required.

A suitable quantity of pollution control equipment, e.g., spill kits containing absorbent pads, absorbent granules, absorbent booms etc. will be kept on site in the event of an emergency. The CEM will check pollution control equipment on a regular basis to ensure that it is adequately maintained (for example ensuring equipment is within date) within the construction areas, “Emergency Grab Packs” or spill kits to be carried in site vehicles and mobile plant and larger kits with fuel bowsers and emergency vehicles.

Static plant such as pumps and generators will be self-bunded or placed on drip trays wherever practicable to prevent leaking materials, from contaminating the ground or surface waters.

Mobile plant to be in good working order, kept clean and fitted with plant 'nappies' at all times.

No washing out of concrete and cement delivery vehicles will take place on-site without suitable provision for the washing out water and provision of a suitable location that is lined with a geotextile to prevent infiltration to ground. Such washing will not be allowed to flow into any drain. Wash water will be adequately contained, prevented from entering any drain, and removed from the Proposed Development site for appropriate disposal at a suitably licenced waste facility.

The site is to be secure to prevent any vandalism that could lead to a pollution incident. Further details of arrangements for dealing with spills, leaks and unplanned emissions, unplanned damage to the environment and other environmental incidents will be provided.

12.1.3. Storage and Handling

Fuel and Lubricants

All fuels will be stored in designated fuel storage areas that will satisfy the requirements of Schedule 3 of The Control of Pollution (Silage, Slurry and Agricultural Fuel Oil) (Scotland) Regulations 2003 (Scottish Government, 2003).

All fuels shall be stored in integral bunded fuel bowsers, designed to hold at least 110% of the contents of the largest container or 25% of the total, whichever is greater. All connections shall be situated within the bund. Fuel shall be stored at least 20 m away from any watercourse, where reasonably practicable. Refuelling within the construction areas shall be undertaken at least 20 m from any watercourses.

Oils and lubricants used within the construction areas will also be stored in temporary impermeable bunded areas or sealed bunded tanks designed to hold 110% of the largest container or 25% of the total, whichever is greater. No oil or fuel shall be stored within 20 m of a watercourse.

Construction waste/debris are to be prevented from entering any surface water drainage or water body by appropriate best practice measures.

Herbicides

Only trained sub-contractors shall apply herbicides, and only where their use is essential. Certificates of competence shall be inspected before application is allowed and a record of application made in accordance with the Control of Pesticides Regulations 1986. Where herbicide use is essential a glyphosate herbicide, suitable for use in or near watercourses and approved by SEPA, shall be used.

Control of Substances Hazardous to Health

All COSHH materials will be stored and handled in accordance with the COSHH Regulations 2002 (UK Government, 2002). A secure COSHH store will be set up within the construction site compound. COSHH assessments and Material Safety Data Sheets shall be held with the COSHH materials. A COSHH register shall be created and maintained on-site.

All site personnel and subcontractors will be made aware of the COSHH requirements through site inductions and specific toolbox talks. Daily site inspections will used to review and monitor the storage and issue of materials.

12.1.4. Pollution Incident Response

As part of the PPCP, the Principal Contractor will incorporate incident response measures. These measures are likely to include:

- A suitably trained emergency environmental crew will be provided by the Principal Contractor to deal with pollution incidents in conjunction with other safety-related incidents as required; and

- An emergency contact list and spill response flowchart shall be displayed on notice boards and on fuel bowsers.

12.2. Outline Construction Noise and Vibration Management Plan

12.2. Outline Construction Noise and Vibration Management Plan

12.2.1. Introduction

This section provides an overview of what will be included within the Construction Noise and Vibration Management Plan.

The noise impact levels resulting from the construction of the Proposed Development must be compliant with the threshold limits defined in the Environmental Impact Assessment. The following threshold noise levels at sensitive receptors have been set using the ‘ABC method’ provided in BS 5228 (British Standards Institution, 2014):

- Weekday daytimes (weekdays 07:00 – 19:00 and Saturdays 07:00 – 13:00) – 65 to 75 dB;

- Evenings and weekends (weekdays 19:00 – 23:00, Saturdays 13:00 – 23:00 and Sundays 07:00 – 23:00) – 55 to 65 dB; and

- Night-time (23:00 – 07:00) – 45 to 55 dB.

Further details are provided within EIA Report Volume 1, Chapter 9.

12.2.2. Noise Management

In addition to the specific mitigation measures detailed within the EIA Report Volume 1, Chapter 9, the following standard mitigation measures will be implemented by the Principal Contractor to minimise noise impacts:

- All construction activity will be undertaken in accordance with good practice as described by BS 5228-1: 2009;

- All construction staff must show consideration to the sensitive receptors, including residential neighbours, and must not generate unnecessary noise when walking to and from the construction sites, or when leaving and arriving at work;

- SMART reversing alarms will be used;

- All personnel involved in the works will receive training and advice on noise minimisation and general good site practice through site-specific training and briefings;

- All materials (including waste materials) shall be handled, stored, and used in a manner that minimises noise. This will include ensuring the efficient handling of materials to avoid unnecessary double handling and to ensure drop heights are minimised. Wherever practicable, materials will be lowered and not dropped from height;

- Plant and equipment:

– Plant will be certified to meet relevant legislation and should be no noisier than would be expected based on the noise levels as stated in BS 5228-1: 2009 Noise and Vibration Control on Construction and Open Sites;

– Noisy plant or equipment will be situated as far as possible from site boundaries and will be fitted with exhaust silencers, maintained in good and efficient working order, and operated in such a manner as to minimise noise emissions. Plant will comply with the relevant statutory requirements;

– Semi-static equipment is to be sited and oriented as far as is reasonably practicable away from noise sensitive receptors and will have localised screening if deemed necessary;

– All plant will be regularly serviced, maintained, and operated in accordance with manufacturers’ instructions;

– Machines that are intermittently used will be shut down in the intervening periods between work or throttled down to a minimum;

– Engine compartments will be closed when equipment is in use;

– Site inductions will highlight the need for vehicle horns and alerts to only be used when absolutely necessary;

– The Principal Contractor will comply with the requirements of the Control of Pollution Act 1974 (with particular reference to Part III), the Environmental Protect Act 1990, the Health and Safety at Work Act 1974 and the Control of Noise at Work Regulations 2005;

– All trade contractors will be made familiar with current noise legislation and the guidance contained in BS 5228-1: 2009 (Parts 1 and 2) which will form a pre-requisite of their appointment;

– Deviation from approved method statements will be permitted only with prior approval from the Principal Contractor and other relevant parties. This will be facilitated by formal review before any deviation is undertaken; and

– Contact details which the public may use shall be provided by the Principal Contractor.

- Traffic and deliveries:

– Vehicles shall not wait or idle on the public highway, with their engines running;

– Routing of HGVs will be agreed with the relevant Local Authorities (ELC);

– Deliveries shall be programmed to arrive during normal working hours, wherever practicable.

- Monitoring, inspections, and reporting:

– The site log/ Daily Progress Report maintained by the Principal Contractors will include record of daily activities, mitigation measures, complaints, weather conditions etc.;

– Areas at risk from excessive noise activities will be inspected daily by the Principal Contractor;

– All complaints will be recorded and investigated, and any corrective actions implemented. Additionally, should any complaints arise regarding vibration they will be investigated, and monitoring measurements taken and analysed, with techniques modified where required; and

– Contact details will be established to provide the opportunity for the local community to raise their concerns if issues with site activities, such as noisy conditions, are causing a nuisance. These contact details will be provided by the Principal Contractor prior to commencing works.

12.3. Outline Construction Dust and Air Quality Management Plan

12.3. Outline Construction Dust and Air Quality Management Plan

12.3.1. Introduction

This section provides an overview of what will be included within the Construction Dust and Air Quality Management Plan.

The Construction Dust and Air Quality Management Plan aims to ensure that the construction of the Proposed Development is carried out such that emissions of dust and other pollutants, including odour, are limited.

The key activities that will generate air pollution are the use of mechanical plant and vehicles, and earthworks. Plant equipment and vehicles will generate exhaust emissions which may impact local air quality (CO2, CO, PM10, PM2.5, NOx, SOx etc.). Dust will be generated through earthworks, such as ground-breaking, top-soil removal and storage.

Construction dust is not typically associated with human health effects as most dust particles are too big to be inhaled, but can cause eye, nose and throat irritation and lead to annoyance if deposited on cars, windows, and other property. Under Part III, Section 79 (Statutory nuisance and inspections therefor) of the Environmental Protection Act 1995, dust can be a statutory nuisance. However, there are no statutory standards for dust deposition which can be used to assess whether a nuisance has occurred, principally due to the normal variability of atmospheric dust, and the wide range of monitoring methods that seek to characterise the dust. Standards are therefore commonly adopted on a “custom and practice” basis (i.e., relevant to specific monitoring methods).

12.3.2. Dust and Air Quality Management

The Institute of Air Quality Management (IAQM) (2014) guidance standard measures for mitigating the impacts of dust during construction and demolition will be followed.

The following mitigation measures will be implemented by the Principal Contractor to minimise dust and air quality impacts:

- Avoid the use of diesel or petrol generators, use mains electricity or battery powered equipment where practicable;

- Use a system of on-site vehicle routes with turning areas and loading areas using suitable speed limits and signage;

- Sheeting of potential dust-generating materials being transported on lorries/vans to and within the Cable Route Site;

- Conduct all cutting and grinding operations in a manner to reduce the risk of dust migration (e.g., wet cutting techniques);

- Adopt dust suppression techniques (e.g., water suppression, damping down access tracks and spraying down stockpiles during dry weather);

- Regularly monitor both on- and off-site to ensure minimal dust and odour impacts upon local neighbours and wildlife;

- Plan site layout so that machinery and dust causing activities are located away from receptors, as far as possible;

- Erect solid screens or barriers around dusty activities that are at least as high as any stockpiles on-site;

- Fully enclose specific operations where there is a high potential for dust production and the Proposed Development construction activity is active for an extensive period;

- Keep site fencing, barriers and scaffolding clean using wet methods;

- Remove materials that have a potential to produce dust as soon as possible, unless being re-used on-site;

- Cover, seed, or fence stockpiles to prevent wind whipping;

- Ensure an adequate water supply on the site for effective dust/particulate matter suppression/mitigation, using non-potable water where possible and appropriate;

- Use enclosed chutes and conveyors, loading shovels, hoppers and other loading or handling equipment and use fine water sprays on such equipment wherever appropriate;

- Ensure equipment is readily available on-site to clean any dry spillages, and clean up spillages as soon as reasonably practicable after the event, using wet cleaning methods;

- Avoid scabbling (roughening of concrete surfaces) if possible;

- Ensure sand and other aggregates are stored in bunded areas and are not allowed to dry out, unless this is required for a particular process, in which case ensure that appropriate control measures are in place;

- Wind conditions shall be monitored throughout construction of the Proposed Development, and backfill material shall be dampened down when dust that could affect the public, road users or surrounding habitat is likely;

- The Principal Contractor will provide road cleaning equipment (e.g., road sweepers) to remove dirt, mud or dust dropped or accumulating on roads to ensure public highways remain unaffected; and

- Damping down access tracks and spraying down stockpiles during dry weather to reduce dust.

Monitoring and communications:

- Display the name and contact details of person(s) accountable for air quality and dust issues at the Proposed Development. This will be the Principal Contractor;

- Dust monitoring will be carried out by the CEM or ECoW on a weekly basis via visual checks to ensure minimal dust and odour impacts upon local neighbours and wildlife. These checks will be carried out and compared with previous recordings to provide a record of site conditions. These will be held as reference to any complaint;

- Carry out daily visual inspections to monitor compliance, record inspection results, and make an inspection log available when requested. Record all inspections of haul routes and any subsequent action in a logbook;

- Increase the frequency of site inspections by the person accountable for air quality and dust issues on-site when specific activities with a high potential to produce dust are being carried out and during prolonged dry or windy conditions;

- Record all dust and air quality complaints, identify cause(s), take appropriate measures to reduce emissions in a timely manner, and record the measures taken;

- Make the complaints log available when requested;

- Record any exceptional incidents that cause dust and/or air emissions, either on or off-site, and the action taken to resolve the situation in the logbook; and

- Wind conditions shall be monitored throughout the works and backfill material shall be dampened down when dust that could affect the public, road users or surrounding habitat is likely.

12.4. Outline Site Waste Management Plan

12.4. Outline Site Waste Management Plan

12.4.1. Introduction

This section provides an overview of what will be included within the Site Waste Management Plan (SWMP). The SWMP will be prepared by the Principal Contractor and will set out the practices to be put in place to ensure the control of waste on site, in a matter not detrimental to the local and wider environment. This encompasses the minimisation of waste and the removal of waste from site where necessary. The SWMP will set out measures to ensure compliance with the Duty of Care responsibilities as prescribed in Section 34 of the Environmental Protection Act 1990 and amended by The Waste (Scotland) Regulations 2012 including;

- Implementation of the waste hierarchy;

- Classification and segregation of waste;

- Waste storage; and

- Waste documentation and transport.

It is anticipated that the construction of the Proposed Development may give rise to the following types of waste:

- wood;

- domestic (e.g., glass, paper, cardboard, plastics, food, sewage);

- metal (e.g., wire, steel);

- soil;

- hazardous substances (e.g., paint, oil, aerosols, batteries); and

- aggregates (e.g., concrete, stone).

12.4.2. Strategy for Waste Reduction

The Principal Contractor will employ the following strategy to achieve maximum reuse and reduce landfill waste:

- Sub-contractors will be contractually obliged to cooperate with the SWMP as part of their tender;

- All staff will be required to engage in site inductions and environmental awareness campaigns;

- Waste management will be incorporated into the design process, including planning for high volumes of waste, consideration of suitable manufacturers and appropriate storage measures;

- The Principal Contractor will identify and segregate waste streams;

- The Principal Contractor will reuse and recycle where possible;

- The Principal Contractor will use suitable storage methods for all materials; and

- Unauthorised waste disposal will be treated as an environmental incident and the Pollution Incidence Response will be implemented. Under no circumstances will waste material be burned or buried on the Proposed Development site.

12.4.3. Development Waste Management Specifics

Classification and Segregation of Waste

The SWMP will list all the site waste streams as identified and classified by the Principal Contractor in line with the methods and categories set out in the Waste Classification Technical Guidance WM3 (SEPA et al. 2017). The identified waste streams will be segregated and the storage and management of each will be set out within the SWMP including measures for special waste and organic material.

Special Waste

“Special waste” is any waste which contains properties that might make it harmful to human health or the environment.

Special waste could arise during construction from the following sources:

- Maintenance of plant and machinery;

- Oily water waste; and

- Environmental spill recovery (small amounts only; larger volumes taken away directly for disposal).

Measures will be set out within the SWMP to ensure that:

- All special waste will be segregated by type from other waste streams;

- All waste oil will be stored in a bunded facility until such times that it is collected; and

- Used filters, rags and absorbents will be stowed in the special waste container in drums or waste oil bags.

12.4.4. Organic Matter Management

Any spoil from excavations must be stored on areas of hardstanding, short grassland, or bare ground adjacent to the works. If anything needs to be stored on vegetation (long grassland or scrub) then the spoil must be wrapped to prevent animal ingress and the ECoW will be required to check the area first.

The waste organic material resulting from site clearance will be managed in-line with a Waste Hierarchy, thus helping to minimise potential environmental issues pertaining to this process.

12.4.5. Storage of Waste

The SWMP will outline measures regarding waste storage to minimise the risk of waste escaping, litter and / or pollution, such as:

- All waste will be stored at the location in which it is generated, or within a designated central waste storage area;

- These designated waste storage areas will be isolated from surface water drains and areas that discharge directly to the water environment;

- Waste will be stored in suitable containers of sufficient capacity to avoid loss, overflow, or spillage;

- Storage of liquid wastes will be on impermeable bunds that hold the capacity of the container;

- Waste will be segregated by waste stream and storage containers will be clearly signed with the waste that they will hold e.g., wood, metal, plastics, or other appropriate waste stream;

- Storage containers will be secure, covered, or enclosed;

- There will be separate containers for special waste;

- Skips will be monitored, and action taken if waste levels are too high; and

- Burning of waste will be prohibited.

12.4.6. Waste Minimisation Measures

The following measures will be implemented to minimise the environmental impacts of construction waste arising from the Proposed Development.

Elimination:

- The Proposed Development will aim to avoid the creation of waste through the detailed design stages. The control of design will reduce the risk of late-stage changes which will require rework and therefore reduce overall waste.

Reduction:

- The Principal Contractor will undertake accurate measurement and ordering of required materials to reduce the volume of waste generated during construction (e.g., ordering standardised sizes to reduce onsite cutting);

- Order materials on a just-in-time basis to reduce onsite storage time;

- The Principal Contractor will ensure the effective and appropriate storage of materials to protect against damage and adverse weather conditions;

- Ensure suppliers have a take-back option for packaging and surplus;

- Maintain good communication with suppliers to reduce the amount of packaging included in deliveries;

- The Principal Contractor will ensure the use of enclosed containers to store waste susceptible to spreading by wind or liable to cause litter; and

- Remove general waste at frequent intervals and keep the site kept clean and tidy.

Waste Storage, handling, and segregation:

- Store wastes in areas a suitable distance (i.e., 20m) away from surface or foul drains and watercourses;

- Segregate all construction wastes, at a minimum, into hazardous and non-hazardous waste streams;

- Segregate construction wastes into dry recyclables;

- Cover waste containers if there is a risk that wastes may be blown out or the wastes contained therein are water sensitive (e.g., plasterboard wastes);

- Store waste oils in suitable sized bunding;

- Use waste signage such as labels that specify waste contents; and

- Secure waste containers. Skips should be lockable if the site is insecure or vulnerable to theft and vandalism.

Re-Use:

- Consider re-using uncontaminated excavated material arising during construction;

- Consider re-using rubble and concrete as backfill, subsoil in landscaping areas and timber offcuts as temporary form work; and

- Where possible, the Principal Contractor will purchase reclaimed or recycled materials or procure materials from sustainable sources.

Recycling:

- The Principal Contractor will designate areas or containers for materials which can be recycled such as plastics, timber, steel, general waste, dry recyclables, batteries, aerosols, etc.

- Off-site Disposal of Site Waste Streams:

- Use of Non-Hazardous Waste Transfer Notes (WTNs) for the off-site disposal of all non-hazardous wastes;

- Use of Special Waste Consignment Notes (SWCNs) for the off-site disposal of all hazardous wastes;

- Retain all WTNs for at least two years and SWCNs for at least three years;

- Only use licensed waste carriers to transport wastes from site and obtain documentation to demonstrate registration;

- Obtain full copies of the Waste Management Licences or Exemptions for the disposal locations of site waste streams;

- Waste contractors will be checked periodically (bi-annually) to ensure they maintain valid licences; and

- Contact the CEM immediately in the event that site wastes are not taken to a licensed waste disposal or recycling facility.

Keep Legislative Records:

- Retain copies of all relevant permits or licences for both carriers and disposal sites;

- Record contact details for all waste carriers and disposal sites;

- Keep audit reports;

- Maintain recycling receipts for non-hazardous waste; and

- Record a description of all waste removed from site including volume and consignment route number.

Monitoring:

- Track the volumes of waste produced using key performance indicators (KPIs) and compare this against targets which will be set at the beginning of the project.

12.4.7. Contaminated Waste

If contaminated soils are recorded or suspected during the works, then works should cease and advice sought from the CEM. Any contaminated waste material produced in this area must be disposed of appropriately by an experienced company licenced to deal with contaminated waste.

12.5. Outline Water Quality Management Plan

12.5. Outline Water Quality Management Plan

This section provides an overview of what will be included within the Water Quality Management Plan. This covers measures specifically related to water pollution from particulates and sediments in run-off and complements the Outline Pollution Prevention and Contingency Plan.

A Water Quality Monitoring Programme will be implemented before, during and after construction to monitor water quality conditions of watercourses which are in hydraulic connectivity with the Proposed Development. Pre-construction monitoring is proposed to develop a baseline water quality dataset for which the construction and post-construction quality can be compared against to assess any potential impacts. The frequency, duration and monitoring methodology will be agreed with SEPA and ELC.

Outlined below are recommendations for mitigation measures to be implemented during construction to control water quality impacts. These mitigation measures take due cognisance of the Water Resources Act 1991 (UK Government, 1991) and the Construction Industry Research and Information Association Report C532 (CIRIA, 2006).

Good practice measures set out in the relevant PPGs, or GPPs have been followed. A review plan for PPGs is currently underway by SEPA, Natural Resources Wales (NRW), and the Northern Ireland Environment Agency (NIEA), replacing them with GPPs. GPPs provide environmental good practice guidance for the whole UK, and environmental regulatory guidance directly to Scotland, Northern Ireland, and Wales.

The relevant guidance includes:

- PPG1: General guide to the preventing pollution (EA, SEPA & EHSNI, 2013);

- GPP2: Above ground oil storage tanks (EA, SEPA & EHSNI, January 2018);

- GPP5: Works and maintenance in or near water (EA, SEPA & EHSNI, February 2018);

- PPG6: Working at construction and demolition sites (EA, SEPA & EHSNI, 2012);

- GPP13: Vehicle washing and cleaning (EA, SEPA & EHSNI, April 2017); and

- GPP21: Pollution incidence response planning (EA, SEPA & EHSNI, June 2021).

The following measures will be put in place to prevent pollution to the water environment:

- Any hazardous materials (such as fuels, oils, and chemicals) will be stored in a secure area with suitable secondary containment (e.g., drip trays, bunds);

- Refuelling of plant and machinery onsite would be carried out in a designated area with suitable measures for the containment of any spillage; plant nappies shall be placed around standing plant and diesel pumps to collect leaks;

- All construction staff will receive appropriate training of what to do in the event of a spillage;

- Provision of spill kits on site for both chemical and oil/fuel used on site;

- Machinery will be regularly maintained and checked to minimise the risk of spillage;

- Restrictions will be placed on the use of machinery near water bodies;

- Treatment of any runoff from construction areas with elevated suspended solids prior to discharge. Approval will be obtained from ELC or SEPA, where required, for any discharges to controlled waters. Treatment measures could include perimeter cut-off ditches, settlement lagoons, overland flow and/or settlement tanks;

- Temporary surface water management systems will be installed early in the construction sequencing and carefully managed to prevent localised flooding or pollution of surface and groundwater from silt and other contaminants;

- Wheel wash facilities will be provided for vehicles moving to and from the site at all entry and exit points. Silty water from wheel washes will require appropriate disposal to prevent unacceptable levels of suspended solids entering any nearby surface water bodies. As noted above, any disposal of surface water generated on site during construction to controlled waters will require consent from SEPA. Wheel washing facilities will be located as far from surface waters as practically possible;

- If dewatering is required on any part of the site, pumped groundwater will be disposed of appropriately and any relevant consents obtained;

- The reseeding of cleared land will be undertaken as soon as practicable, to minimise exposed land and the entrainment of sediment by overland flow. This can be managed by ensuring construction plant/materials are stored on hardstanding surfaces where possible. Where this is unavoidable, the Principal Contractor will ensure any compacted soil is loosened as soon as possible following completion of the works; and

- The Principal Contractor will manage and dispose of foul water and sewage effluents from site facilities, complying with GPP 4: Treatment and disposal of wastewater where there is no connection to the public foul sewer, the governmental guidance document on Groundwater Protection, other relevant guidance, and the following measures, as appropriate:

– Containment by temporary foul drainage facilities and disposal off-site by licensed contractors; and

– By preference, connection to the local foul sewer system as agreed with the relevant authorities; or where a foul sewer is not present, appropriate treatment and discharge to a watercourse or soakaway with approval from the SEPA, where required. If not permitted, provisions need to be adopted to remove the liquid from site for disposal, such as via tanker.

The following measures will be implemented during construction to minimise the risk of pollution to controlled waters and accord with GPP2:

- Any containers of contaminating substances on site will be leak-proof and kept in a safe and secure building or compound from which they cannot leak, spill or be open to vandalism. The containers will be protected by temporary impermeable bunds with a capacity of 110% of the contents of the largest container or 25% of the total, whichever is greater. Areas for transfer of contaminating substances will be similarly protected.

- All refuelling, oiling, and greasing will take place above drip trays or on an impermeable surface which provides protection to underground strata and watercourses and away from drains as far as reasonably practicable. Vehicles will not be left unattended during refuelling.

- Only construction equipment and vehicles free of oil/fuel leaks which could cause material contamination will be permitted on site. Drip trays/nappies will be placed below static mechanical plant.

- All wash down of vehicles and equipment will take place in designated areas and wash water will be prevented from passing untreated into watercourses and will comply with GPP 13.

- GPP 5 will be followed when carrying out works near water. As far as reasonably practicable, only biodegradable hydraulic oils will be used in equipment working in or over watercourses.

- Appropriate measures to be taken to protect erodible earthwork surfaces.

- The hazards of silt pollution will be emphasised in the Environmental Induction, including examples of recent significant enforcement action.

- No water will ever be pumped directly into a watercourse without appropriate controls and consents; i.e., all water pumped into a watercourse must be treated first to settle or remove suspended solids.

- The minimum area of topsoil will be stripped at any one time.

- The spread will be ‘lipped’ or bunded as it crosses a watercourse to prevent direct run-off. Where necessary silt fencing will be installed.

12.6. Outline Soils Management Plan

12.6. Outline Soils Management Plan

This section provides an overview of what will be included in the Soils Management Plan. The SMP will be developed by the Principal Contractor in conjunction with ELC, NatureScot, SEPA, Historic Environment Scotland (HES), and the ECoW. This plan will set out the site and soil specific measures to protect soils present on site.

Outlined below are mitigation measures to be implemented during construction to control soil quality impacts:

- Earthmoving works will be carried out in accordance with BSI Code of Practice for Earth Works BS6031:2009 and an earthworks method statement will be produced where more than 50 m³ of spoil is to be excavated.

- Stripping soil following periods of heavy rainfall will be avoided.

- Areas of exposed ground will be reduced so far as reasonably practicable.

- Top and subsoil stockpiles will be segregated.

- All soils will be carefully handled.

- Stockpiles to reduce erosion losses will be protected so far as reasonably practicable where storage is longer than 6 months. Stockpiles will also be protected from flooding.

- Traffic will avoid soil stockpiles so far as reasonably practicable.

- Where practicable, reinstating soils following periods of heavy rainfall will be avoided.

- Subsoil will be reinstated to maintain natural drainage patterns and avoid settlement.

- Topsoil will be reinstated by rendering into a loose and workable condition as well as contouring to maintain the profile with the adjacent undisturbed area.

- Effective temporary and / or permanent soil erosion control measures will be implemented.

- Suitable, adequate, and effective control measures will be implemented and maintained to prevent run-off from stockpiles contaminating surface waters.

- Disturbed areas and mounds of topsoil/subsoil will be re-graded to blend with the surrounding landform.

12.7. Outline Habitat Management Plan

12.7. Outline Habitat Management Plan

The Proposed Development will ensure that, during construction activities, valuable habitat areas are protected or reinstated and, where appropriate, enhanced to ensure opportunities for net gain in biodiversity.

Best practice guidelines (CIEEM, 2018) will be followed throughout the construction of the Proposed Development to protect existing wildlife within the site. This includes obtaining appropriate species licences prior to the commencement of works and implementing mitigation strategies to ensure compliance with relevant wildlife legislation.

Specific requirements for mitigation within the site include standard embedded ecology measures:

- Adverse effects should be avoided or minimised, either through the design of the Proposed Development or subsequent mitigation measures. The Proposed Development has been designed to avoid areas of higher ecological sensitivities wherever possible.

- Where impacts on important ecological receptors cannot be avoided, they should be minimised. Minimisation takes many forms, with subsequent design iteration being tweaked and amended where possible to reduce potential ecological impacts. Minimisation has been achieved in several areas by the proposed design. For example:

– The onshore cabling will be installed alongside tracks and/or field margins wherever possible to minimise habitat loss and/or disturbance.

– Proximity to watercourses has been avoided wherever possible.

– Areas considered to be more sensitive in terms of protected habitats such as semi-natural woodland, wetland habitats, and coastal habitats have been avoided wherever possible.

– Trenchless technology is to be used as an alternative to open trenching techniques to install sections of the onshore cable including at the landfall within Barns Ness SSSI to minimise habitat loss and/or disturbance.

- Where there are significant residual adverse ecological effects despite the mitigation proposed, these should be offset by appropriate compensatory measures.